Floating ball valve

Floating Ball Valve

Floating ball valve is mainly characterized by the ball without support shaft, the ball is held by the two valve seat which is “floating” state, it is mainly used in pipelines to cut off, distribution and change the direction of media flow.

Floating ball valves are mainly characterized by seat seal design, reliable inverted seal valve stem, fire protection static electricity function, automatic pressure relief and locking device and other structural features.

Product information

| NO | Parts | Standard | Stainless steel | Weak acid | Low temperature |

|---|---|---|---|---|---|

| 1 | Body | ASTM A216 WCB | ASTM A351 CF8M | ASTM A216 WCB | ASTM A352 LCB |

| 2 | Seal ring | Flexible graphite | Flexible graphite | Flexible graphite | Flexible graphite |

| 3 | Seat ring | ASTM A276 420 | ASTM A182 F316 | ASTM A276 420 | ASTM A276 420 |

| 4 | Ball | ASTM A276 420 | ASTM A182 F316 | ASTM A276 420 | ASTM A276 420 |

| 5 | Seal gasket | 316+Graphite | 316+Graphite | 316+Graphite | 316+Graphite |

| 6 | Bolt | ASTM A193 B7 | ASTM A193 B8 | ASTM A193 B7M | ASTM A320 L7M |

| 7 | Nut | ASTM A194 2H | ASTM A194 8 | ASTM A194 2HM | ASTM A194 4 |

| 8 | Spring | 65Mn | 65Mn | 65Mn | 65Mn |

| 9 | Spring seat | ASTM A276 420 | ASTM A182 F316 | ASTM A276 420 | ASTM A276 420 |

| 10 | Fire-proof metal gasket | 304 | 304 | 304 | 304 |

| 11 | Anti-static spring | Stainless steel | Stainless steel | Stainless steel | Stainless steel |

| 12 | Stem | ASTM A182 F6a | ASTM A182 F316 | ASTM A182 F6a | ASTM A350 LF2/ENP |

| 13 | Packing | Flexible graphite | Flexible graphite | Flexible graphite | Flexible graphite |

| 14 | Bonnet | ASTM A216 WCB | ASTM A351 CF8M | ASTM A216 WCB | ASTM A352 LCB |

| 15 | Gland | ASTM A216 WCB | ASTM A351 CF8M | ASTM A216 WCB | ASTM A352 LCB |

| 16 | Wrench | ASTM A216 WCB | ASTM A351 CF8M | ASTM A216 WCB | ASTM A352 LCB |

| 17 | Bolt | ASTM A193 B7 | ASTM A193 B8 | ASTM A193 B7M | ASTM A193 L7M |

| 18 | Position card | ANSI 1025 | ANSI 1025 | ANSI 1025 | ANSI 1025 |

| 19 | Ring | ANSI 1066 | ANSI 1066 | ANSI 1066 | ANSI 1066 |

Structural Features and Usages

1. The opening and closing and the opening extent is usually determined by the position of the wrench. When the wrench is parallel with the pipelines, the valve is at opening position; when vertical with the pipelines, the valve is closed.

2. Design 90° position plate and install lock when necessary, to prevent wrong operation.

3. Seat is designed with spring-loading metal seal, which separates the bottom of the seat from the inner wall of the body and leaves a space. When the ball presses at the seat surface, seat presses the bottom spring to get preload and make up. Therefore, this decreases the damage of seal surface.

4. Use T-type stem to prevent the stem blowing out due to the increase of the pressure of the cavity. Back seat is designed to ensure the packing seal. The valve is widely used in the pipes of food, pharmacy, petroleum, chemical, gas, steel, environment protection, paper to transfer the medium or cut it off.

Technical requirements

| Design standard | Design standard | API 6D, ASME B 16.34 | DIN 3357-1, EN 12516-1 | API 6D |

|---|---|---|---|---|

| End connection | ASME B16.5, ASME B16.47 | DIN 2542-2545, EN1092, EN17292 | GOST 33259 | |

| Structure length | API 6D, ASME B16.10 | DIN 3202 | ASME B16.10, GOST 3706 | |

| Test and inspect | API 6D, API 598 | DIN 3230/3, EN 12266 | GOST 9544 | |

| Applied conditions | Applied medium | Natural gas, liquedied petroleum gas | ||

| Applied temperature | -196℃~450℃ | |||

| Operation | Worm gear, Pneumatic, Electric, Pneumatic-hydraulic | |||

Applicable standards

Steel ball valves: API 608/API 6D

Steel ball valves: ISO 14313

Fire safe: API 607

Anti static: API 608

Steel valves: ASME B 16.34

Face to face: ASME B 16.10

End flanged: ASME B 16.5

Butt welding ends: ASME B16.25

Inspection and test: API 598/API 6D

Available modifications

Trim change

End connection modification

Packing and gasket change

Operator mounting pad

Hand wheel extension

Pressure equalizing

Anti-static of Fire safe

Client specified coating

Weld end bore change

Oxygen & chlorine cleaning & packing

Designing Features of Floating Ball Valves

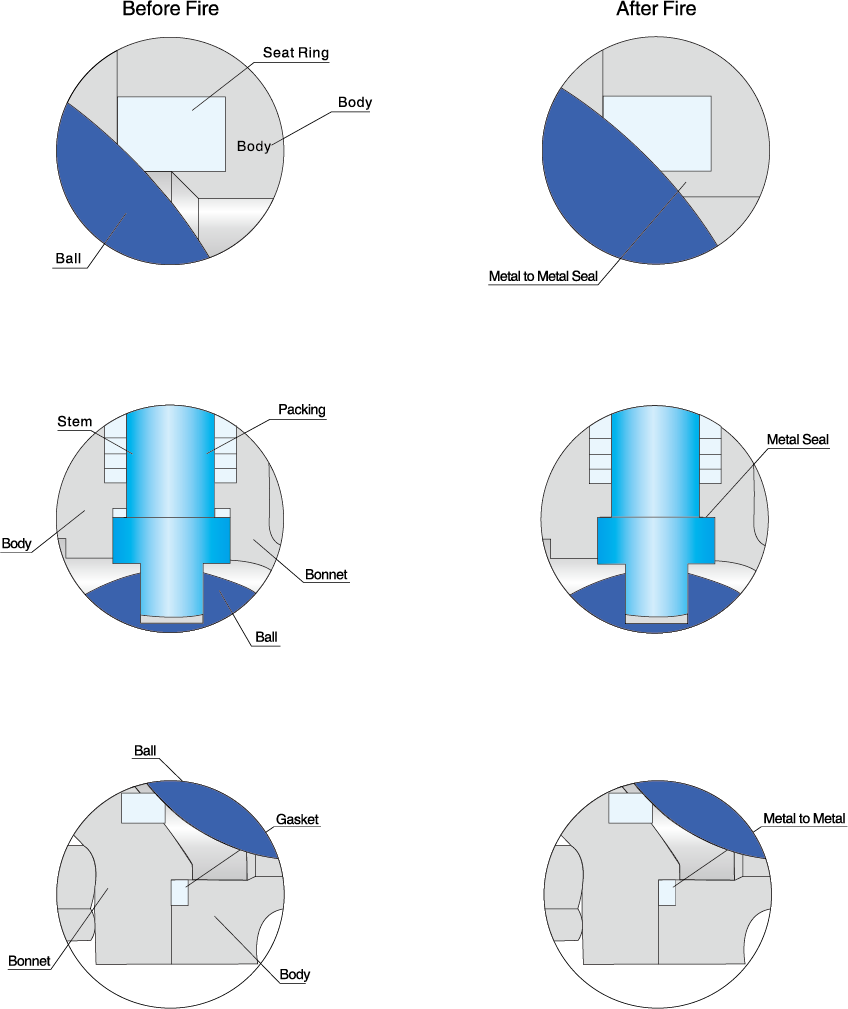

Fire Proof Seat Ring

When non-metal resilient seats are destroyed in a fire in factory, the upstream medium pressure pushes the ball into the downstream metal seal lip to cut off the line fluid and prevent the internal leakage due to a secondary metal-to-metal seals.

The fire proof design of all floating ball valves are designed according to API 607, and passed the fire test.

Anti-blow out stem

The stem is designed with integral T-type shoulder to provide blow-out proof effectively. It is internally inserted as the backseat function to assure stem sealing safety at all pressures.

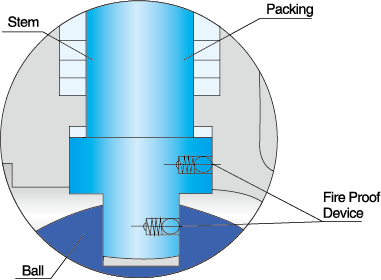

Fire Proof Device

According to customer‘s request, ball valves can be designed as anti-static structure, that is, a spring is set between stem and ball, and stem and the ball, so that the electricity generated during the opening and closing of the valves is conducted through the electricity channel to the below the ground, diminishing the static. This prevents the lighter of static to burn the medium, and ensure the safety of the system.

Wrong-operation Prevention

For the valve installed outdoors, o easy to operate wrong, and in the condition that shocks heavily to make the hand wheel operates wrong, a lock hole is set where the valve opens and closes. If necessary, the valves will be locked to ensure safety.